In-Mold Decorations in Modern Production: A Comprehensive Guide

In-Mold Decorations in Modern Production: A Comprehensive Guide

Blog Article

Understanding In-Mold Decorations: Techniques, Trends, and Ideal Practices for Ideal Outcomes

In the world of manufacturing, the art of in-mold decors stands as an essential aspect of item layout and manufacturing. As sectors consistently look for ingenious methods to improve visual charm and capability, mastering the complexities of in-mold decorations has actually emerged as an essential capability. From choosing the appropriate materials to incorporating advanced design fads, the trip towards attaining optimum lead to this domain name is multifaceted. By delving right into the approaches, patterns, and best practices that underpin effective in-mold design procedures, companies can unlock a world of possibilities that not only raise the visual allure of their items however likewise improve production effectiveness and reinforce consumer engagement.

Material Choice

Product choice is a critical aspect of understanding in-mold decors, as it straight impacts the quality and sturdiness of the end product. When picking products for in-mold designs, it is vital to consider factors such as compatibility with the molding procedure, the wanted aesthetic outcome, and the environmental problems the item will certainly face. Polycarbonate materials like abdominal, polycarbonate, and polypropylene are generally utilized for in-mold decorations as a result of their flexibility and ability to attain complex styles. These materials use outstanding moldability, making it possible for makers to create intricate shapes and patterns with accuracy.

Additionally, the picked material must have good attachment homes to ensure that the decoration sticks strongly to the substrate during the molding process. Bond between the material and the design is important for stopping delamination and making certain lasting aesthetic allure. Additionally, products with high warmth resistance are favored for in-mold designs, especially for items that will certainly be revealed to elevated temperatures during their lifecycle. By very carefully picking the suitable material for in-mold designs, suppliers can boost the total quality and toughness of their items, meeting the expectations of both end-users and clients.

Design Development

A necessary aspect in advancing the field of in-mold decorations is the continual exploration and implementation of layout innovation strategies. Design advancement plays an important role in boosting the aesthetic allure, capability, and overall high quality of products produced making use of in-mold decoration processes. By including cutting-edge design aspects, makers can separate their products in the marketplace, draw in consumers, and remain in advance of rivals.

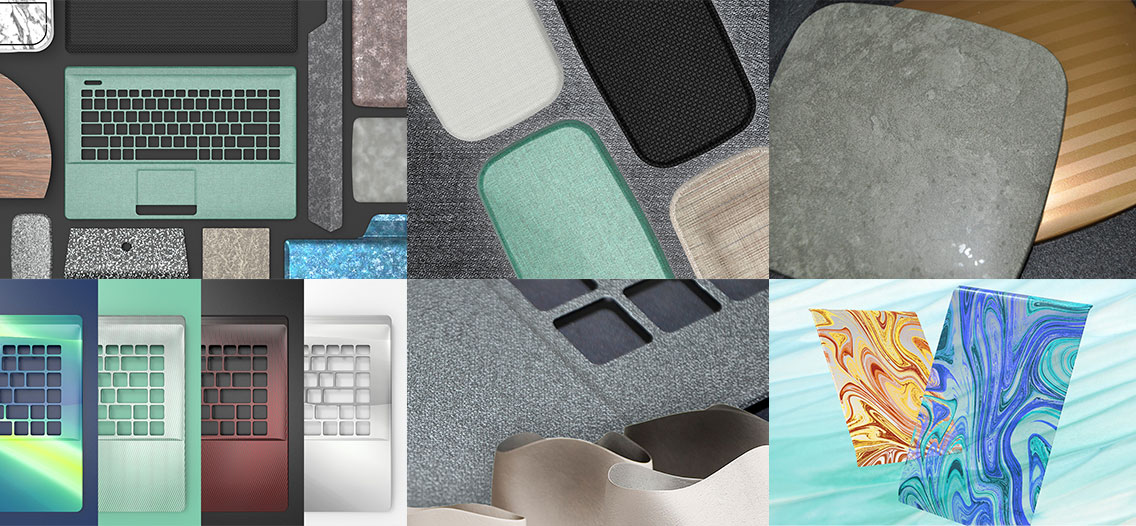

Among the crucial elements of design development in in-mold designs is the combination of intricate patterns, structures, and graphics that were previously challenging to accomplish with standard design approaches. Advanced modern technologies such as 3D printing and electronic design tools make it possible for designers to develop complex and detailed styles that can be flawlessly transferred onto molded parts. Additionally, using dynamic shades, metal coatings, and unique impacts like gloss or matte structures can additionally raise the visual charm of in-mold enhanced products.

Moreover, design technology extends past aesthetic appeals to encompass functional enhancements such as ergonomic forms, incorporated features, and personalized elements that cater to particular individual demands. By embracing layout development, producers can open new possibilities for product, customization, and imagination distinction in the competitive landscape of in-mold designs.

Production Performance

Effective manufacturing procedures are vital for translating the innovative designs established in the area of in-mold decors into premium completed items that satisfy market needs and customer assumptions. In the realm of in-mold decors, production efficiency includes various key aspects that contribute to the overall success of the manufacturing procedure.

Automation not just accelerates the production process yet also enhances accuracy and repeatability, leading to a much more consistent and high-quality end item. In general, an all natural approach to manufacturing performance is vital in making the most of the capacity of in-mold decor methods and attaining optimal outcomes in the competitive market landscape.

Quality Assurance Measures

What are the crucial strategies for making certain strict high quality control steps in the realm of in-mold designs? Quality control actions are paramount in in-mold decor procedures to ensure the manufacturing of flawless and high-quality finished products.

Using innovative innovations such as computerized assessment systems can additionally improve the top quality control procedure by offering precise and trusted data for evaluation. These systems can find imperfections that might be missed out on by manual assessments, consequently improving general item quality and uniformity.

Normal training and development programs for workers associated with the in-mold design procedure can likewise add to preserving high-quality standards. By enlightening personnel on finest methods, quality expectations, and the value of interest to information, business can promote a culture of high quality awareness throughout the organization.

Customer Charm

To enhance the marketability of in-mold design items, providing and recognizing to consumer choices play a crucial function in determining their charm and success. Consumer allure in in-mold decorations is affected by numerous elements, including style looks, shade selections, resilience, and total functionality. Customers are significantly seeking customized and unique items that show their originality and design. Supplying customization alternatives such as individualized designs, shade variants, and textural components can substantially improve the appeal of in-mold design items.

Verdict

In-mold decorations supply a flexible and reliable way to enhance item appearances. Grasping in-mold designs requires an all natural technique that thinks about all elements of the manufacturing procedure to guarantee success.

In the realm of manufacturing, the art of in-mold decorations stands as an essential facet of product layout and manufacturing. Layout advancement plays a vital role in improving the aesthetic appeal, performance, and overall top quality of products manufactured making use of in-mold design processes.One look what i found of the key aspects of style development in in-mold decors is the combination of intricate patterns, textures, and graphics that were previously challenging to attain with typical design methods.Effective manufacturing procedures are essential for translating the ingenious styles established in the area of in-mold designs right into top quality finished items that meet market needs and consumer expectations. Supplying customization alternatives such as personalized designs, shade variants, and textural components can significantly enhance the appeal of in-mold decoration items.

Report this page